+rfid +systems +for +manufacturing From tracking assets in labs to monitoring WIP on manufacturing floors, this technology has revolutionized countless industries. But what exactly is RFID? How does it work its magic? This comprehensive guide will help you to explore in detail about this game-changing technology. Curious how RFID Transforms Asset Tracking?

corrupted. Game can't use this tag, but if its a generic blue tag it can sometimes be written over. Placing it on a NFC reader (like a New 3DS) fixes these tags. dead. Game doesn't see the tag, .I beleive All handsets with Android Kitkat, having NFC, supports HCE. Based on above, here is .

0 · types of rfid systems

1 · rfid tracking systems for manufacturing

2 · rfid technology pros and cons

3 · rfid systems for small business

4 · rfid production tracking system

5 · rfid manufacturing inventory management

6 · rfid manufacturing companies

7 · rfid for small business

This document contains the release information for the NXP NFC Reader .

Ready to Revolutionize Your Manufacturing Operations? Discover the full potential of RFID technology for your manufacturing processes with ASC Software. Enhance efficiency, reduce errors, and gain unparalleled visibility into every aspect of your production.

Ready to Revolutionize Your Manufacturing Operations? Discover the full potential of RFID technology for your manufacturing processes with ASC Software. Enhance efficiency, reduce errors, and gain unparalleled visibility into every aspect of your production.

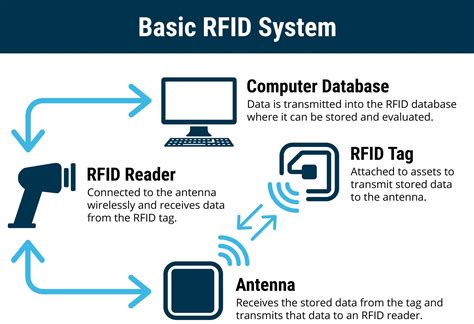

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?RFID systems enable seamless tracking and tracing of goods throughout the supply chain, from manufacturing facilities to distribution centers and delivery vehicles. RFID tags identify and monitor shipments, optimize route planning, and streamline logistics operations, leading to faster delivery times, reduced transportation costs, and enhanced . RFID (Radio Frequency Identification) Systems are wireless communication systems that use radio waves to identify, categorize, and track objects, people, or animals by attaching RFID tags to them, which can be read by RFID readers without requiring line-of .From tracking assets in labs to monitoring WIP on manufacturing floors, this technology has revolutionized countless industries. But what exactly is RFID? How does it work its magic? This comprehensive guide will help you to explore in detail about this game-changing technology. Curious how RFID Transforms Asset Tracking?

types of rfid systems

Specialized Industrial RFID systems are available to give real-time data with the accuracy and dependability required for automation, just-in-time, and custom manufacturing. Automotive production provides a wide range of examples of RFID tracking with qualified software and hardware to capture data on the assembly line, in specialized workshops .

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. Let's explore how RFID transforms operations in critical areas of a manufacturing facility: Supply Chain Optimization. In the realm of the supply chain, RFID enables manufacturers to monitor supplier inventory levels with precision, ensuring seamless inventory management and timely restocking.

We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly. Industrial RFID systems have been shown to improve quality control for the manufacturing industry. Industrial RFID tags can be read from a distance, which means that they can be used to track objects as they move through the manufacturing process.

rfid tracking systems for manufacturing

Ready to Revolutionize Your Manufacturing Operations? Discover the full potential of RFID technology for your manufacturing processes with ASC Software. Enhance efficiency, reduce errors, and gain unparalleled visibility into every aspect of your production.

The use of RFID in manufacturing has skyrocketed as plants look for innovative ways to improve efficiency, asset tracking and safety. But how does it work?RFID systems enable seamless tracking and tracing of goods throughout the supply chain, from manufacturing facilities to distribution centers and delivery vehicles. RFID tags identify and monitor shipments, optimize route planning, and streamline logistics operations, leading to faster delivery times, reduced transportation costs, and enhanced . RFID (Radio Frequency Identification) Systems are wireless communication systems that use radio waves to identify, categorize, and track objects, people, or animals by attaching RFID tags to them, which can be read by RFID readers without requiring line-of .From tracking assets in labs to monitoring WIP on manufacturing floors, this technology has revolutionized countless industries. But what exactly is RFID? How does it work its magic? This comprehensive guide will help you to explore in detail about this game-changing technology. Curious how RFID Transforms Asset Tracking?

rfid technology pros and cons

Specialized Industrial RFID systems are available to give real-time data with the accuracy and dependability required for automation, just-in-time, and custom manufacturing. Automotive production provides a wide range of examples of RFID tracking with qualified software and hardware to capture data on the assembly line, in specialized workshops . In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle.

Let's explore how RFID transforms operations in critical areas of a manufacturing facility: Supply Chain Optimization. In the realm of the supply chain, RFID enables manufacturers to monitor supplier inventory levels with precision, ensuring seamless inventory management and timely restocking. We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly.

rfid systems for small business

rfid production tracking system

rfid manufacturing inventory management

On my iPhone 8 (iOS 14.2 beta 4), I can choose the NFC Tag Reader in control panel. On my iPhone Xs (iOS 14.1) this is not an option at all. Can't see NFC Tag Reader in control panel. Why can't it be added on iPhone .

+rfid +systems +for +manufacturing|rfid technology pros and cons