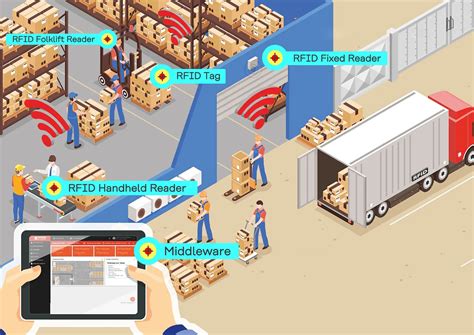

warehouse management system using rfid RFID helps streamline warehouse operations by reducing the time needed for stocktaking, locating items, and processing shipments. Warehouse staff no longer need to manually scan or search for products, freeing them to focus on value-added tasks such as quality checks or customer service. Cleveland Browns 33 at Pittsburgh Steelers 36 on January 5th, 2003 - Full team and player stats and box score . Wild Card - Cleveland Browns at Pittsburgh Steelers - January 5th, 2003. via .

0 · using rfid to track inventory

1 · rfid warehouse tracking system

2 · rfid warehouse management system requirements

3 · rfid warehouse inventory management

4 · rfid tracking systems for inventory

5 · rfid in warehouse management pdf

6 · rfid disadvantages

7 · pros and cons of rfid

And that's what it was. On Wednesday (!) I got both the "Your card has been sent" email and the "Your card has arrived" email (at the same time!). I checked the wallet app and there was the manual activation button. I held the .

With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be .

What is RFID System in warehousing? With RFID warehouse management software, items can be scanned and cataloged from anywhere, even hidden in boxes or .With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously. What is RFID System in warehousing? With RFID warehouse management software, items can be scanned and cataloged from anywhere, even hidden in boxes or pallets. RFID tags can even be detected and read remotely and simultaneously.RFID helps streamline warehouse operations by reducing the time needed for stocktaking, locating items, and processing shipments. Warehouse staff no longer need to manually scan or search for products, freeing them to focus on value-added tasks such as quality checks or customer service.

What is the use of RFID in warehouse management? In warehouse management, RFID strengthens and streamlines myriad activities – from order dispatch, and stock location, to cycle counting. It also trims down human errors, giving a thrust to overall efficiency. Discover how implementing an RFID warehouse management system can improve operational efficiency and get the most out of your warehouse. Learn about the benefits, tips for successful implementation, and if it is right for you.

Discover how to optimize warehouse operations with RFID technology in this comprehensive guide to RFID warehouse management. RFID (Radio Frequency Identification) technology has revolutionized the way warehouses manage their . Warehouse Management Solution (WMS) consists of hardware and software frameworks including RFID technology to help managers keep track of products within the warehouse. The inventory management system may be the first thing that comes to mind when considering RFID technology.

What Is RFID Warehouse Management? RFID, or Radio-Frequency Identification, is commonly used in warehouse management and logistics to track and manage inventory and assets more efficiently. It relies on radio waves to transmit data between an .

In today’s fast-paced logistics environment, the integration of Radio Frequency Identification (RFID) technology in warehouse management is not just an innovation—it’s becoming a necessity. This technology provides a competitive edge by enhancing the accuracy and efficiency of inventory management.By using RFID tags to track items, warehouses can improve their efficiency and accuracy. This guide will teach you how to decide if an RFID system is appropriate for your warehouse and how to implement it successfully.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

What is RFID System in warehousing? With RFID warehouse management software, items can be scanned and cataloged from anywhere, even hidden in boxes or pallets. RFID tags can even be detected and read remotely and simultaneously.RFID helps streamline warehouse operations by reducing the time needed for stocktaking, locating items, and processing shipments. Warehouse staff no longer need to manually scan or search for products, freeing them to focus on value-added tasks such as quality checks or customer service. What is the use of RFID in warehouse management? In warehouse management, RFID strengthens and streamlines myriad activities – from order dispatch, and stock location, to cycle counting. It also trims down human errors, giving a thrust to overall efficiency. Discover how implementing an RFID warehouse management system can improve operational efficiency and get the most out of your warehouse. Learn about the benefits, tips for successful implementation, and if it is right for you.

Discover how to optimize warehouse operations with RFID technology in this comprehensive guide to RFID warehouse management. RFID (Radio Frequency Identification) technology has revolutionized the way warehouses manage their . Warehouse Management Solution (WMS) consists of hardware and software frameworks including RFID technology to help managers keep track of products within the warehouse. The inventory management system may be the first thing that comes to mind when considering RFID technology. What Is RFID Warehouse Management? RFID, or Radio-Frequency Identification, is commonly used in warehouse management and logistics to track and manage inventory and assets more efficiently. It relies on radio waves to transmit data between an . In today’s fast-paced logistics environment, the integration of Radio Frequency Identification (RFID) technology in warehouse management is not just an innovation—it’s becoming a necessity. This technology provides a competitive edge by enhancing the accuracy and efficiency of inventory management.

using rfid to track inventory

smart card id online

warehouse management system using rfid|pros and cons of rfid